The world of manufacturing is constantly evolving, and one of the most promising advancements in recent years is 3D printing in manufacturing. This innovative technology is transforming how products are designed, prototyped, and produced, offering numerous benefits such as cost reduction, improved efficiency, and enhanced creativity. In this article, we will explore the significant impact of 3D printing on the manufacturing industry, its applications, and future prospects.

Understanding 3D Printing

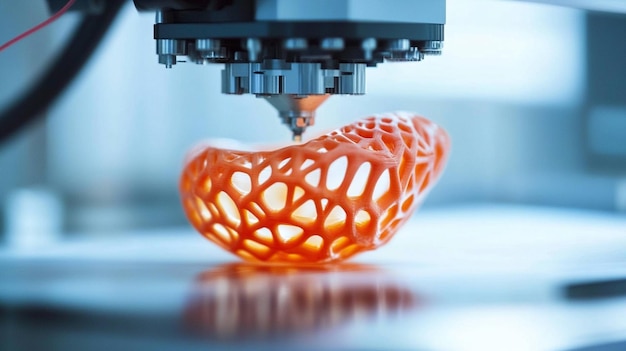

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. This is achieved by laying down successive layers of material until the desired shape is formed. Unlike traditional manufacturing methods, which often involve subtractive processes, 3D printing builds objects layer by layer, minimizing waste and enabling complex designs.

The Evolution of 3D Printing in Manufacturing

Early Beginnings

The journey of 3D printing in manufacturing began in the 1980s with the development of stereolithography, a technology that uses ultraviolet lasers to cure photopolymer resins. Over the years, advancements in materials, software, and hardware have expanded the capabilities of 3D printing, leading to its widespread adoption across various industries.

Current Trends

Today, 3D printing is no longer limited to prototyping but has evolved into a viable production method for a wide range of applications. Industries such as aerospace, automotive, healthcare, and consumer goods have embraced this technology to streamline production, reduce costs, and create customized products. For example, the automotive industry uses 3D printing to produce complex parts with reduced weight and increased strength, improving fuel efficiency and performance.

Benefits of 3D Printing in Manufacturing

Cost Savings

One of the most significant advantages of 3D printing is its potential for cost savings. Traditional manufacturing methods often require expensive tooling and molds, leading to high setup costs. In contrast, 3D printing eliminates the need for tooling, allowing manufacturers to produce small batches or even one-off customized products at a fraction of the cost. This is particularly beneficial for startups and small businesses that lack the resources for large-scale production.

Efficiency and Speed

3D printing enables rapid prototyping and production, significantly reducing lead times. Designers can quickly iterate and test their ideas, leading to faster product development cycles. Additionally, 3D printing allows for on-demand manufacturing, reducing the need for inventory and minimizing storage costs.

Design Flexibility

Traditional manufacturing methods often impose design limitations due to the constraints of tooling and machining. In contrast, 3D printing offers unparalleled design flexibility, allowing manufacturers to create intricate and complex geometries that would be impossible or cost-prohibitive with conventional methods. This opens up new possibilities for innovation and customization, enabling companies to differentiate their products in a competitive market.

Applications of 3D Printing in Manufacturing

Aerospace Industry

The aerospace industry has been one of the early adopters of 3D printing, utilizing the technology for producing lightweight components with improved performance. By reducing the weight of aircraft parts, manufacturers can achieve fuel savings and reduce emissions, contributing to a more sustainable aviation industry.

Healthcare Sector

In the healthcare sector, 3D printing has revolutionized the production of medical devices, prosthetics, and implants. Customized implants and prosthetics can be tailored to fit individual patients, improving comfort and functionality. Moreover, 3D printing enables the creation of complex anatomical models for surgical planning and training, enhancing the precision and success of medical procedures.

Consumer Goods

3D printing is also making its mark in the consumer goods industry, allowing companies to offer personalized products that cater to individual preferences. From customized phone cases to bespoke fashion accessories, 3D printing empowers consumers to express their unique style and preferences.

Challenges and Limitations

Material Limitations

Despite its many advantages, 3D printing in manufacturing still faces challenges, particularly in terms of material limitations. While the range of materials available for 3D printing is expanding, it is still limited compared to traditional manufacturing materials. This can restrict the types of products that can be produced and their performance characteristics.

Quality Control

Ensuring consistent quality in 3D printed parts can be challenging due to variations in materials, processes, and equipment. Manufacturers must implement rigorous quality control measures to ensure that 3D printed products meet industry standards and customer expectations.

The Future of 3D Printing in Manufacturing

Technological Advancements

The future of 3D printing in manufacturing looks promising, with ongoing advancements in technology and materials. Researchers are exploring new materials, such as high-strength polymers and advanced composites, to expand the capabilities of 3D printing. Additionally, improvements in printing speed and precision will further enhance the efficiency and quality of 3D printed products.

Integration with Traditional Manufacturing

As 3D printing continues to evolve, it is likely to be integrated with traditional manufacturing methods, creating hybrid production processes that combine the best of both worlds. This integration will enable manufacturers to leverage the strengths of each approach, optimizing efficiency, cost, and quality.

Conclusion

3D printing in manufacturing is revolutionizing the industry, offering unprecedented opportunities for innovation, customization, and efficiency. While there are challenges to overcome, the potential benefits far outweigh the limitations. As technology continues to advance, 3D printing will play an increasingly important role in shaping the future of manufacturing. To learn more about the impact of technology on the printing industry, visit Hybrid Printing Systems.

FAQs

What is 3D printing in manufacturing?

3D printing in manufacturing refers to the use of additive manufacturing technologies to create three-dimensional objects from digital files, layer by layer, offering benefits such as cost reduction and design flexibility.

How does 3D printing benefit the aerospace industry?

In the aerospace industry, 3D printing is used to produce lightweight, high-performance components, leading to fuel savings and reduced emissions.

What are the challenges of 3D printing in manufacturing?

Challenges include material limitations and quality control. The range of available materials is limited, and ensuring consistent quality in printed parts can be difficult.

This article contains affiliate links. We may earn a commission at no extra cost to you.