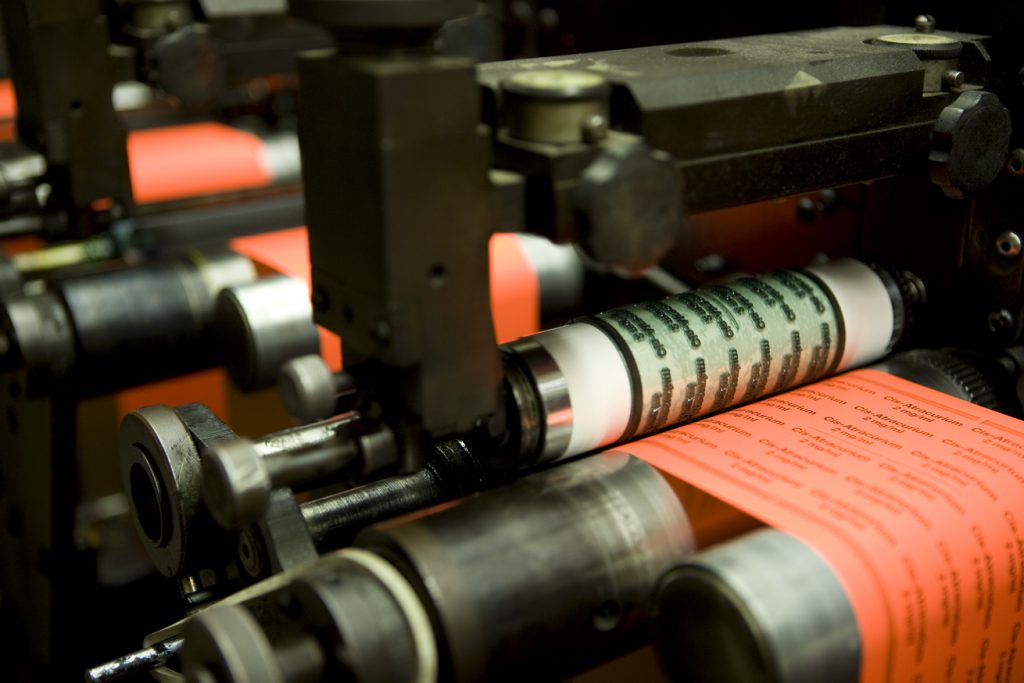

The world of flexographic printing is vast and intricate, with many components working in harmony to produce the quality prints that marketing professionals and businesses rely on. At the heart of this printing process lie the anilox rollsthe unsung heroes that ensure precision and consistency in printed colors. However, like every hero, they necessitate care and maintenance. Thus, understanding anilox cleaning methods is paramount to ensuring longevity and efficiency in your printing operations.

In this article, we dive deep into the various approaches to maintaining these crucial components. Whether you are new to the domain or seeking to refine your knowledge, this exploration of anilox cleaning methods will equip you with invaluable insights and practical advice.

Why Is Anilox Cleaning Important?

The functionality and efficiency of anilox rolls are vital for maintaining high-quality print results. Over time, ink deposits and residues can build up, affecting print accuracy and quality. Regular and appropriate cleaning not only extends the lifespan of the anilox but also prevents costly production downtimes.

Types of Anilox Cleaning Methods

1. Manual Cleaning

Manual cleaning is a traditional approach that involves using specially formulated chemicals and manual scrubbing. It’s a hands-on method that, when done correctly, ensures detailed attention to every part of the anilox roll.

2. Ultrasonic Cleaning

Ultrasonic cleaning uses high-frequency sound waves to agitate a fluid. This advanced technique effectively removes contaminants, making it a popular choice for those seeking thorough and efficient cleaning.

3. Laser Cleaning

A relatively new technology, laser cleaning involves the use of laser beams to remove ink residues. It’s a precise method that minimizes wear and is environmentally friendly, as it doesn’t require chemicals.

4. Baking Soda Blasting

This method utilizes baking soda particles projected at high speeds to clean the anilox. It’s gentle yet effective, maintaining the surface integrity of the rolls.

5. Chemical Cleaning

Chemical cleaning involves specialized solutions that chemically dissolve deposits on the anilox surface. It is crucial to select the right chemicals that are compatible with your specific type of anilox roll.

How to Choose the Right Method

Choosing the right anilox cleaning method is crucial and depends on various factors including the type of ink used, the material of the anilox roll, and the level of residue buildup. Each technique has its pros and cons, and the best choice often requires a bit of experimentation and knowledge of your printing process needs.

Regular Maintenance Benefits

Regular maintenance greatly enhances the performance of anilox rolls. Consistent cleaning prevents ink buildup, reduces potential damage, and ensures uniform print qualitybenefits that can enhance productivity and reduce operational costs.

Challenges in Anilox Cleaning

Despite the advantages of regular maintenance, challenges exist, such as selecting the right cleaning method and adhering to schedules without disrupting production. It’s essential to have a well-trained team that understands these nuances.

The Role of Technology

Technological advancements in printing have introduced automated cleaning solutions. These innovations increase the efficiency and safety of cleaning processes, offering support to businesses in maintaining high standards of operation.

Environmental Considerations

With increasing awareness about environmental impacts, many printing companies opt for cleaning solutions and methods that minimize chemical waste and reduce the overall environmental footprint.

Expert Tips for Effective Cleaning

Consistency is key. Regular inspections, proper storage, and using recommended cleaning solutions play crucial roles in maintaining the integrity of your anilox rolls. Engage with manufacturers for advice that aligns with specific roll requirements.

Common Mistakes to Avoid

Avoid using incompatible chemicals or harsh abrasives that can damage your rolls. Inadequate rinsing post-cleaning can also leave residues, negatively impacting print quality.

FAQs

1. What should be the frequency of anilox cleaning?

Regular cleaning depends on usage frequency and ink types. Typically, cleaning every couple of weeks is advised, but high-volume operations may require weekly maintenance.

2. Can I automate the anilox cleaning process?

Absolutely, many advanced systems exist that automate the cleaning process, ensuring consistency and saving time.

3. Are there eco-friendly cleaning options available?

Yes, methods such as laser cleaning and various biodegradable chemicals offer eco-friendly alternatives.

Understanding and implementing proper anilox cleaning methods becomes indispensable in maintaining the vitality and efficiency of flexographic printing operations. For more detailed insights on how flexographic printing works, see [How Flexographic Printing Works](https://newprintingera.com/how-flexographic-printing-works/) which offers extensive guidance. Or visit [What Is Flexo Printing](https://www.flexologic.nl/news/what-is-flexo-printing/) for an external perspective.