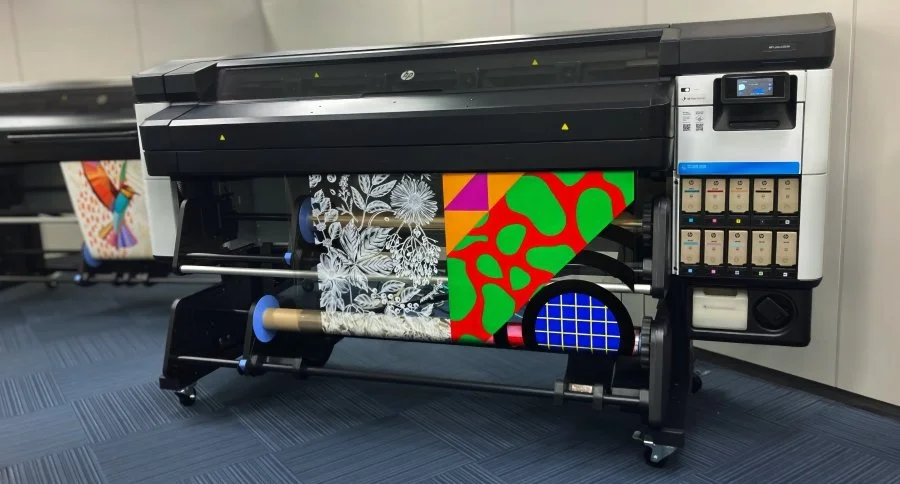

Consistent and precise color reproduction is essential for anyone working with latex printing technology. Whether you’re producing banners, wall coverings, or fine art prints, maintaining color accuracy in latex printing ensures your output matches your vision and your clients’ expectations. This guide covers proven strategies, practical tools, and expert insights to help you achieve reliable, repeatable color results with your latex printer.

From calibrating your monitor to understanding media profiles and ink behavior, there are several factors that influence how colors appear on your final prints. We’ll explore the most effective methods for controlling these variables, highlight common pitfalls, and point you to additional resources for troubleshooting and advanced optimization.

If you’re interested in learning more about compatible materials, check out our guide on what substrates work with latex printing for a detailed look at media options and their impact on print quality.

Understanding the Importance of Color Management

Managing color is a critical step in any professional print workflow. Without a robust color management process, even the best printers and inks can produce inconsistent or inaccurate results. In latex printing, this challenge is heightened by the variety of substrates and environmental factors that can affect ink behavior.

A well-implemented color management system helps ensure that the colors you see on your monitor are faithfully reproduced on your printed output. This not only saves time and materials but also builds trust with clients who expect reliable color matching for branding and design projects.

Monitor Calibration: The Foundation of Accurate Color

The first step toward reliable color accuracy in latex printing is calibrating your monitor. An uncalibrated display can mislead you about the true colors in your digital files, leading to disappointing print results. Use a dedicated calibration device to adjust your monitor’s color settings, brightness, and contrast.

Regular calibration—ideally once a month—ensures your screen remains a trustworthy reference. This is especially important in environments where lighting conditions change or multiple monitors are used in the workflow.

Choosing the Right Media and Ink Combinations

The choice of substrate and ink has a significant impact on color reproduction. Different materials absorb and reflect ink in unique ways, affecting vibrancy and tonal range. Always use media profiles specifically created for your printer and the substrate you’re using. These profiles help your RIP (Raster Image Processor) software translate digital colors into precise ink values for each material.

For more on selecting optimal materials, our article on best materials for latex printing provides an in-depth comparison of popular options and their color performance.

Printer Profiling and ICC Profiles

ICC profiles are essential for translating digital color data into accurate print output. These profiles describe how your printer, ink, and media interact, allowing your RIP software to compensate for any color shifts. Most latex printers come with a library of manufacturer-provided profiles, but for critical work, consider creating custom profiles using a spectrophotometer.

Custom profiling is especially valuable when using specialty substrates or third-party inks. It ensures that your specific setup is accounted for, minimizing unexpected color variations.

Optimizing Printer Settings for Consistent Results

Fine-tuning your printer settings is another key factor in achieving reliable color. Adjust parameters such as ink density, print mode, and curing temperature to match your chosen media. Many printers allow you to save custom presets for frequently used materials, streamlining your workflow and reducing the risk of errors.

For step-by-step instructions on optimizing your device, see our resource on how to choose latex printer settings.

Environmental Factors Affecting Color Output

Environmental conditions like temperature and humidity can influence ink drying and color consistency. Latex inks are water-based and can be sensitive to changes in ambient conditions. Maintain a stable print room environment and allow prints to cure fully before evaluating color accuracy.

If you encounter unexpected shifts or inconsistencies, check for drafts, direct sunlight, or fluctuations in humidity that could be impacting your results.

Routine Maintenance and Troubleshooting

Regular maintenance of your latex printer helps prevent issues that can compromise color quality. Clean printheads, check for clogged nozzles, and replace worn parts as needed. If you notice persistent color problems, consult our guide on common latex printing problems for solutions to typical issues.

For more advanced troubleshooting, our troubleshooting latex printer issues article provides a comprehensive checklist to diagnose and resolve color-related concerns.

Advanced Tips for Professional-Level Color Precision

- Soft Proofing: Use soft proofing tools in your design software to preview how colors will appear on your chosen substrate before printing.

- Consistent Lighting: Evaluate prints under standardized lighting conditions (such as D50 or D65) to avoid misjudging color due to ambient light shifts.

- Regular Re-Profiling: Update your ICC profiles periodically, especially when changing ink batches or media suppliers.

- Documentation: Keep detailed records of printer settings, media types, and environmental conditions for each job. This makes it easier to replicate successful results or troubleshoot issues.

- Education: Stay current with the latest developments in latex printing technology by following manufacturer updates and industry resources. For example, HP’s overview of large-format latex printing technology offers valuable insights into new features and best practices.

Frequently Asked Questions

How often should I calibrate my monitor for latex printing?

For best results, calibrate your monitor at least once a month. If your workspace experiences frequent changes in lighting or you use multiple displays, consider calibrating more frequently to maintain consistent color reference.

What is the role of ICC profiles in color management?

ICC profiles act as a bridge between your digital files and the physical print, ensuring accurate color translation based on your specific printer, ink, and media combination. Using the correct profile is essential for achieving predictable and repeatable color results.

Can environmental factors really affect color accuracy?

Yes, temperature and humidity can impact how latex inks cure and appear on different substrates. Maintaining a stable print environment helps minimize color shifts and ensures consistent output across multiple jobs.

What should I do if my prints don’t match what I see on screen?

Start by checking your monitor calibration and ensure you’re using the correct ICC profile for your printer and media. Also, verify that your printer settings and environmental conditions are optimal. If issues persist, consult troubleshooting guides or consider creating custom profiles for your workflow.