The printing industry has seen significant advancements over the years, but one aspect that often requires attention is the effectiveness of drying systems in offset presses. As a marketing professional, understanding the intricacies of these systems is crucial in ensuring high-quality print output. In this article, we will explore the various types of drying systems, their benefits, and how they are transforming the world of offset printing.

Introduction to Offset Printing

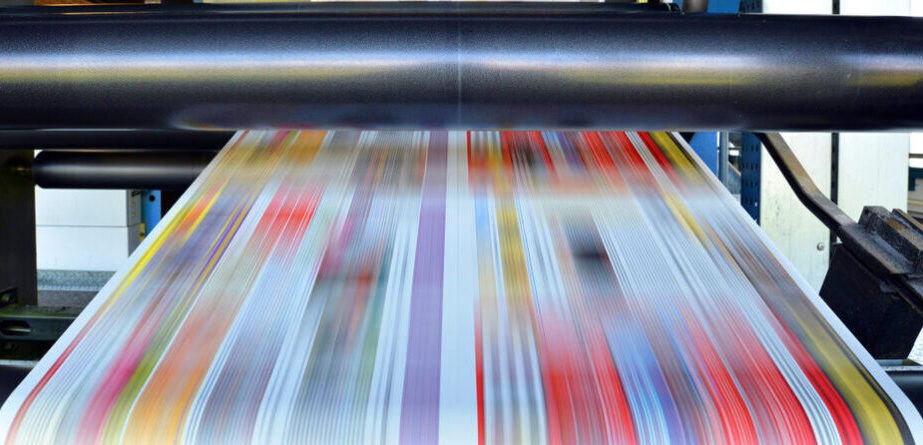

Offset printing is a widely used technique where the inked image is transferred from a plate to a rubber blanket, and then to the printing surface. This method is favored for its high-quality output and efficiency in large-scale print jobs. However, the drying process plays a pivotal role in the final product quality, making it essential to have effective drying systems in place.

Understanding Drying Systems in Offset Presses

Drying systems in offset presses are designed to efficiently dry the ink on the substrate, ensuring a smudge-free and crisp print. These systems are vital in maintaining the integrity of the print and preventing any delays in the printing process.

Types of Drying Systems

There are several types of drying systems used in offset presses, each with its unique advantages:

- Infrared Drying: This system uses infrared radiation to heat the ink, speeding up the drying process. It is effective for water-based inks and provides consistent results.

- UV Curing: UV drying systems use ultraviolet light to cure inks instantaneously. This method is popular for its quick drying times and ability to handle complex print jobs efficiently.

- Hot Air Drying: Hot air systems circulate heated air over the printed material, promoting evaporation and drying of the ink. This method is suitable for a variety of substrates.

Benefits of Efficient Drying Systems

Integrating advanced drying systems in offset presses offers numerous benefits:

- Enhanced Print Quality: Proper drying ensures that the ink does not smudge, resulting in sharp and vibrant prints.

- Increased Productivity: Faster drying times lead to quicker turnaround, allowing print jobs to be completed more efficiently.

- Cost-Effectiveness: By preventing reprints and reducing waste, efficient drying systems help in cutting costs.

Challenges in Implementing Drying Systems

Despite their benefits, there are challenges associated with implementing drying systems in offset presses. These include the initial cost of installation, maintenance requirements, and the need for skilled operators to manage the systems effectively.

Overcoming Challenges

To overcome these challenges, it is essential to invest in training for operators and ensure regular maintenance of the systems. Additionally, choosing the right drying system that matches the specific needs of the print job can optimize performance.

The Future of Drying Systems in Offset Printing

The future of drying systems in offset presses looks promising, with ongoing research and development aimed at improving efficiency and reducing environmental impact. Innovations such as energy-efficient systems and eco-friendly inks are expected to further revolutionize the industry.

FAQ

What are the types of drying systems used in offset presses?

There are several types of drying systems used in offset presses, including infrared drying, UV curing, and hot air drying. Each system offers unique benefits and is suited to different types of print jobs.

Why are drying systems important in offset presses?

Drying systems are crucial in offset presses as they ensure the ink dries properly, preventing smudges and maintaining high print quality. They also improve productivity by reducing drying times.

How can I choose the right drying system for my needs?

Choosing the right drying system depends on the type of ink and substrate used, as well as the specific requirements of the print job. Consulting with a professional or conducting thorough research can help in making an informed decision.

For more insights into the world of offset printing, you can check this in-depth guide on how offset printing works.

For further reading on related topics, consider visiting safety protocols in flexo pressrooms, spot colors in offset printing, and offset press components explained.

Conclusion

In conclusion, understanding and implementing effective drying systems in offset presses is vital for achieving high-quality prints and improving productivity. As the industry continues to evolve, staying informed about the latest advancements in drying technology will ensure that your printing operations remain competitive and efficient.

This article contains affiliate links. We may earn a commission at no extra cost to you.