In the dynamic world of printing, achieving accurate and vibrant colors is crucial. Flexo printing color correction is an essential process that ensures the final printed materials meet the desired expectations. This article aims to provide an in-depth understanding of color correction in flexo printing, a topic of great importance for marketing professionals and anyone involved in the printing industry.

What is Flexo Printing?

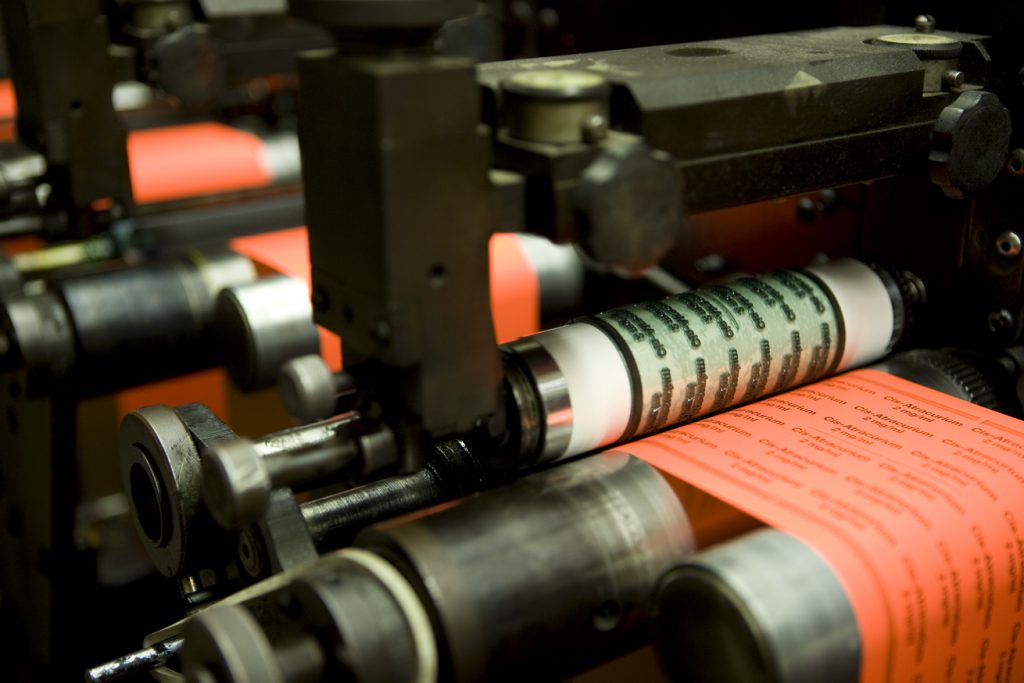

Flexographic printing, commonly known as flexo printing, is a versatile printing method used for various substrates, including paper, plastic, and metal. It is widely employed for packaging, labels, and cartons. The process involves using flexible relief plates and fast-drying inks, making it suitable for high-volume production. For a detailed explanation of the flexo printing process, you can visit Flexopedia.

The Importance of Color Correction in Flexo Printing

Color correction in flexo printing is vital to maintain brand consistency and ensure that printed materials accurately reflect the intended design. Inaccurate colors can lead to costly reprints and damage a brand’s reputation.

Understanding Color Theory

Color theory is the foundation of effective color correction. It involves understanding primary, secondary, and tertiary colors, as well as color harmonies and contrasts. Familiarity with color theory enables printers to adjust colors to achieve the desired outcome.

Common Color Issues in Flexo Printing

Some common color issues in flexo printing include color shifts, inconsistency across prints, and incorrect color matches. These issues can arise from various factors such as ink formulation, substrate properties, and environmental conditions.

Steps to Achieve Accurate Color Correction

1. Calibration of Printing Equipment

Calibrating printing equipment is the first step toward achieving accurate color correction. This involves adjusting the press settings to ensure consistent color output across different print runs.

2. Use of Color Management Systems

Color management systems (CMS) are essential tools for maintaining color accuracy. They help in creating color profiles that ensure the colors on the screen match the printed output. For insights on ink drying systems in flexo, check here.

3. Proofing Techniques

Proofing techniques allow printers to identify and correct color issues before the actual print run. Digital proofs and press proofs are common methods used to ensure color accuracy.

4. Ink Formulation and Adjustment

Proper ink formulation is crucial for achieving the desired color. Adjusting the ink’s viscosity, pH, and other properties can significantly impact the final print quality.

Challenges in Flexo Printing Color Correction

Substrate Variability

Different substrates absorb ink differently, affecting color consistency. Printers must adjust their processes to accommodate these variations.

Environmental Factors

Temperature and humidity can impact ink drying time and color consistency. Monitoring and controlling environmental conditions is essential for optimal results. For more on solvent recovery processes in flexo, see here.

Future Trends in Flexo Printing

The flexo printing industry is continuously evolving, with advancements in technology enhancing color accuracy and efficiency. Innovations such as improved ink formulations, advanced color management software, and automated printing processes are setting new standards in the industry. Stay updated on market trends by visiting here.

Adoption of Digital Technologies

Integration of digital technologies in flexo printing is becoming prevalent. These technologies offer precise control over color correction, leading to better print quality and reduced waste.

Sustainability in Flexo Printing

As environmental concerns grow, the flexo printing industry is adopting sustainable practices. This includes using eco-friendly inks and substrates, as well as efficient waste management systems.

Conclusion

In conclusion, flexo printing color correction is a critical aspect of the printing process that ensures high-quality output. By understanding color theory, utilizing color management systems, and keeping up with industry trends, professionals can achieve consistent and accurate colors in their prints. For further reading on the flexographic printing process, check out this article.

FAQs

What is the role of color management systems in flexo printing?

Color management systems help maintain color accuracy by creating profiles that ensure consistent color output across different devices and substrates.

Why is substrate variability a challenge in color correction?

Different substrates absorb ink differently, leading to variations in color consistency. Printers need to adjust their processes to account for these differences.

How does environmental control impact color correction?

Environmental factors like temperature and humidity can affect ink drying and color consistency, making it important to monitor and control these conditions for optimal results.