The world of packaging is ever-evolving, with technological advancements facilitating more efficient and effective processes. One such advancement is flexo printing for corrugated boxes, a crucial technique in the packaging industry. This method has gained popularity due to its ability to produce high-quality prints on various substrates, especially on corrugated boxes. In the paragraphs below, we delve into the intricacies of this versatile printing method, exploring its inner workings, benefits, and future potential.

Understanding Flexo Printing

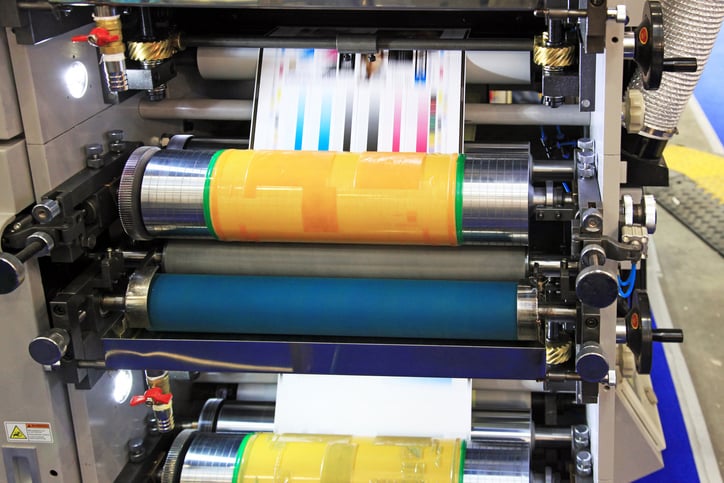

To appreciate the benefits of flexo printing for corrugated boxes, it is important to first understand what flexo printing, or flexographic printing, entails. Flexographic printing is a high-speed printing technique that utilizes flexible relief plates to transfer ink onto a substrate. This method is particularly effective for printing on non-porous materials, making it ideal for packaging.

The process begins with the creation of a flexible plate that is wrapped around a print cylinder. The substrate, which in this case is a corrugated box, passes through the press, where ink is applied directly from the plate to the substrate. How does this process work?

The Advantages of Flexo Printing for Corrugated Boxes

There are numerous reasons why manufacturers and printers opt for flexo printing when producing corrugated boxes:

- Cost-Effectiveness: Flexographic printing offers a cost-efficient solution for large-scale production runs, primarily due to the low cost of the plates and the high speed of the printing process.

- Versatility: This printing method accommodates a wide range of inks and materials, ensuring compatibility with various substrates, including corrugated boards.

- Quality Output: With advances in flexographic technology, it is now possible to achieve photographic-quality prints. Learn about print quality

- Environmental Benefits: Flexo printing is often more environmentally friendly compared to other methods since it uses water-based inks and produces less waste.

Recent Innovations in Flexographic Printing

Like any technology, flexographic printing has seen several innovations that enhance its efficiency and output quality:

Advanced Plate Technology

One significant advancement is in plate technology. Modern photopolymer plates provide sharper image reproduction and longer durability, reducing the need for frequent replacements. This innovation translates to savings on time and resources.

Enhanced Ink Formulations

Recent developments in ink formulations have allowed for improved color accuracy and consistency. These eco-friendly inks offer enhancements in drying time and adhesion to varied substrates.

Automation and Digital Advancements

Automation technologies have streamlined the flexographic printing process, reducing human error and improving efficiency. Coupled with digital advancements, flexographic presses can now integrate digital workflow solutions, optimizing the entire production process.

Challenges and Solutions in Flexo Printing

Despite its advantages, flexographic printing is not without its challenges.

Plate Production Times

The production of flexographic plates can be time-consuming. However, recent developments in plate-making technologies are reducing time-to-market. Explore plate-making

Color Matching

Achieving precise color matching can be challenging due to variations in inks and substrates. Advanced color management systems are now employed to address these issues effectively.

The Future of Flexo Printing

As the packaging industry strives to meet growing demands for sustainability and efficiency, the future of flexo printing for corrugated boxes appears promising.

Emerging technologies are focusing on reducing energy consumption and waste while enhancing print quality and process efficiency. The integration of smart technologies into flexographic presses will further augment performance and adaptability to new market trends.

Conclusion

As we move toward a more sustainable future in manufacturing and production processes, embracing flexo printing as a viable and innovative solution for corrugated boxes can yield substantial benefits. By being informed and adopting new practices, businesses can leverage these advancements, ensuring competitiveness and environmental responsibility in this rapidly evolving field.

FAQ

What is Flexographic Printing?

Flexographic printing is a method using flexible relief plates for printing on various substrates, ideal for packaging due to its speed and cost-effectiveness.

Why Choose Flexo Printing for Corrugated Boxes?

Flexo printing is preferred for its ability to produce high-quality prints on rough surfaces like corrugated boxes, with the advantages of cost-effectiveness and environmental benefits.

What Are the Recent Innovations in Flexo Printing?

Recent innovations include advanced plate technology, enhanced ink formulations, and automation in processes, all contributing to improved efficiency and print quality.