In today’s rapidly evolving world of printing technology, flexo printing stands out as a pivotal method, especially when it comes to producing security labels. This article explores how flexo printing for security labels is transforming industries by providing high-quality, secure, and efficient printing solutions. As marketing professionals seek innovative methods to ensure product authenticity, understanding the nuances of flexo printing becomes crucial.

Understanding Flexo Printing Technology

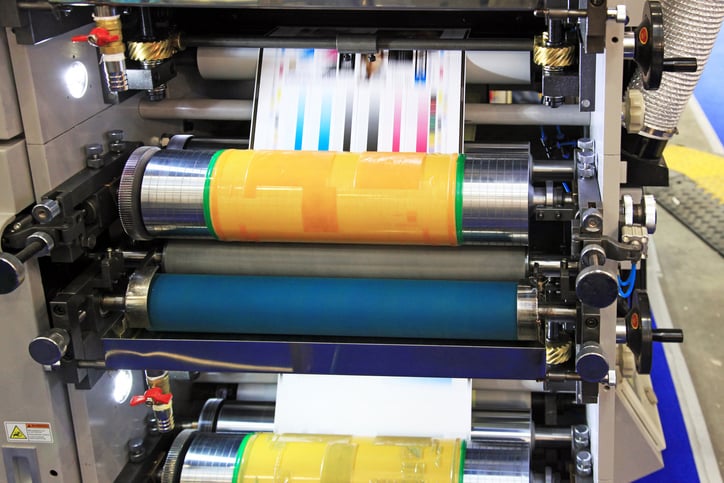

Flexo printing, short for flexographic printing, is a modern version of letterpress that utilizes flexible relief plates. It is highly regarded for its ability to print on various substrates, including plastic, metallic films, cellophane, and paper. This versatility makes it ideal for security labels that require durability and precision.

What Makes Flexo Printing Unique?

A key feature of flexo printing is its speed and efficiency. The process uses fast-drying inks and involves a continuous roll-fed system, allowing for high-volume production. This is essential for industries relying on security labels to protect their products from counterfeiting and tampering.

The Role of Security Labels

Security labels play a crucial role in safeguarding products against unauthorized access and tampering. They are essential in industries such as pharmaceuticals, electronics, and luxury goods. These labels often incorporate features like holograms, QR codes, and barcodes to enhance security.

Importance of Security in Today’s Market

With the rise of counterfeit products, the demand for robust security labels has never been higher. Flexo printing offers the precision and adaptability needed to produce these intricate labels effectively.

Advantages of Flexo Printing for Security Labels

The combination of flexo printing with security labels offers numerous advantages:

- Durability: The use of high-quality inks and substrates ensures that labels are resistant to environmental factors.

- Customization: Flexo printing allows for customized designs, meeting specific security needs.

- Cost-Effectiveness: Its ability to handle long print runs makes it economically viable.

Case Studies: Successful Applications

Many industries have successfully implemented flexo printing for their security labels. For instance, the pharmaceutical industry uses this technology to ensure that medications are safe and genuine.

Challenges in Flexo Printing

Despite its advantages, flexo printing does face challenges, such as maintaining ink adhesion and reducing press downtime. However, ongoing advancements in technology are continuously addressing these issues.

For more insights into overcoming these challenges, you can explore ink adhesion in flexography and press downtime reduction.

Future of Flexo Printing in Security Labels

As technology evolves, so does flexo printing. Innovations like eco-friendly inks and digital enhancements are paving the way for more sustainable and secure labels.

Flexo Printing vs. Other Printing Methods

While flexo printing has its strengths, it’s vital to compare it with other methods like digital and offset printing to understand its unique benefits for security labels.

Key Differentiators

Flexo printings ability to print on diverse materials and its high-speed production capabilities give it an edge over other methods, particularly when security and precision are critical.

Emerging Trends in Flexo Printing

The flexo printing industry is witnessing trends such as increased automation and the integration of AI for quality control. These trends are enhancing the production of security labels to meet ever-changing market demands.

Impact of E-commerce on Security Labels

With the rise of e-commerce, the need for reliable security labels is more significant than ever. Flexo printing is at the forefront of meeting these demands. Learn more about the intersection of flexo printing and e-commerce packaging by visiting flexo in e-commerce packaging.

Conclusion

Flexo printing for security labels is an indispensable tool for modern businesses seeking to protect their products and maintain brand integrity. As new technologies emerge, the capabilities of flexo printing will continue to expand, offering even more robust solutions for security labels.

For further details on flexography, you might find this guide helpful.

FAQ Section

What is the main advantage of flexo printing?

The primary advantage of flexo printing is its versatility and speed. It can print on a wide range of materials quickly and efficiently.

How does flexo printing improve security labels?

Flexo printing enhances security labels by providing high-resolution printing, enabling the integration of security features like holograms and QR codes.

Is flexo printing environmentally friendly?

Yes, many advancements in flexo printing focus on using eco-friendly inks and sustainable practices to minimize environmental impact.