In the bustling world of retail marketing, standing out is key to success. One of the cutting-edge methods that is making a significant difference today is flexographic printing. This versatile printing technique has become increasingly popular in the retail sector due to its capacity to produce high-quality results efficiently and cost-effectively.

Understanding how flexographic printing is utilized in retail can help businesses enhance their product presentation and customer experience. As marketing professionals seek innovative ways to attract customers, this technology offers a plethora of advantages. But why has it become such a crucial component of the retail industry?

What is Flexographic Printing?

Flexographic printing is a modern form of relief printing, which uses a flexible plate. This method is ideal for printing on a wide variety of materials, expanded usage from labels to packaging material. The process is swift and efficient, making it suitable for large-scale operations as often seen in the retail sector.

History and Evolution of Flexographic Printing

Flexographic printing first emerged in the early 20th century, originally developed as a way to print on packaging materials. Over the decades, it has evolved significantly, incorporating advanced technology and materials to enhance its efficiency and quality. The advancements have helped it maintain its relevance in the modern retail environment.

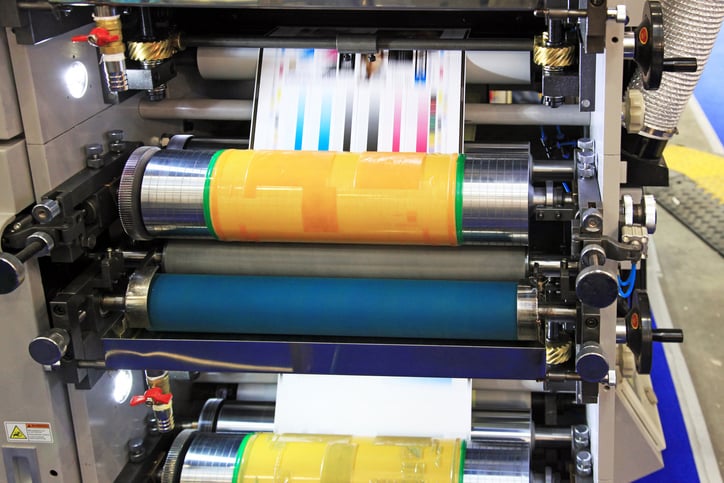

How Flexographic Printing Works

The key to the process involves flexible relief plates which are wrapped around rotating cylinders on a web press. [This explanatory guide](https://newprintingera.com/how-flexographic-printing-works/) provides an in-depth understanding of the mechanics behind the printing method. The ink is transferred from the ink fountain to the printing plates, and then to the substrate, in swift succession, creating sharp, vibrant images.

Flexographic Printing in Retail Packaging

Retail packaging significantly benefits from the adaptable nature of flexographic printing. The ability to print on different substrates, such as plastics, metallic films, and paper, gives retailers the capability to experiment with various packaging designs. This versatility meets the demands of diverse retail products.

The Role in Brand Representation

A brand’s packaging is often the first point of interaction with consumers. By using flexographic printing, companies can ensure that their packaging stands out with vivid colors and clear graphics. This process supports brand consistency across different products and packaging styles.

Environmental Advantages of Flexographic Printing

Sustainability is a growing concern in the retail industry, and businesses are seeking ways to reduce their environmental footprint. Flexographic printing is known for its eco-friendliness. It uses water-based inks that reduce volatile organic compound (VOC) emissions, making the process more environment-friendly.

Recyclability and Material Efficiency

The materials used in flexographic printing, such as print plates, can be recycled. Additionally, the efficiency of the printing process results in less waste, aligning with the growing demand for sustainable business practices.

Cost-Effective Solutions for Retail Businesses

The cost-effectiveness of flexographic printing makes it a preferred choice for many businesses. The process allows for high-volume print runs at a lower cost compared to other printing methods. This affordability makes it accessible to both large retailers and smaller businesses looking to optimize their cost structures.

The Impact on Supply Chain and Inventory

Efficient printing methods like flexographic printing also streamline the supply chain. Quick turnarounds mean that products can be delivered and stocked rapidly, reducing lead times and improving inventory management.

Meeting Demands Swiftly

Products need to be adapted quickly to meet changing market demands. With the speed and adaptability of this printing technique, businesses can swiftly respond to new trends and consumer demands, maintaining competitive advantage.

Digital Integration in Flexographic Printing

Modern advancements have allowed for the integration of digital features in flexographic setups, providing enhanced precision and quality. Digital technology brings added precision, marrying the speed of flexography with the accuracy of digital printing methods.

Future Trends in Flexographic Printing

The trends in flexographic printing indicate a growing merge with digital processes, increasing its competitiveness in the market. [Explorations in wide-web applications](https://newprintingera.com/wide-web-flexographic-printing/) showcase potential for further economic scalability and innovation.

Challenges and Considerations

Despite its advantages, there are challenges associated with flexographic printing, such as the initial setup cost and complexity of the rotary setup. However, its long-term benefits outweigh these initial hurdles for many businesses in the retail space.

Education and Training

Operators need to be thoroughly trained to handle the equipment efficiently. Training ensures that the printing quality is maintained and reduces the chances of costly errors during production.

Keeping Up With Technological Improvements

As technology advances, keeping up with new equipment and software improvements is critical. Retailers and printers must stay updated to fully exploit the potential of flexographic printing in retail.

Emerging Technologies

New technologies continue to emerge that make printing processes faster and more efficient. This expands possibilities not only in retail but across different industries. Learn more about these advances with an insight into [flexo vs digital printing](https://newprintingera.com/flexographic-printing-vs-digital-printing/).

User Experience and Product Appeal

Flexographic printing plays a critical role in enhancing user experience and product appeal, ensuring that products are presented attractively to customers.

Conclusion: The Ongoing Evolution

With its versatility, efficiency, and cost-effectiveness, flexographic printing heralds an exciting future for retail businesses. As technology continues to evolve, so too will the capabilities of this printing method, making it an essential asset in modern marketing strategies.

FAQ: Common Questions About Flexographic Printing in Retail

What Materials Can Be Printed Using Flexography?

Flexographic printing can be used on a wide variety of materials, including paper, plastic, metallic films, and cardboard, making it ideal for diverse retail packaging needs.

How Is Flexographic Printing Environmentally Friendly?

This method uses water-based inks and generates less waste, contributing to lower environmental impact compared to traditional printing methods.

Why Choose Flexographic Printing Over Other Methods?

Flexographic printing offers fast production times, adaptability to various materials, and cost efficiencies, making it a popular choice for retail businesses focused on quick market responsiveness.