The world of printing is rich and varied, with flexographic printing plates playing a significant role. These plates are crucial to a process that has evolved over the years to meet new industry demands. Whether you’re printing packaging for goods, labels for products, or any other forms of media, flexographic printing provides a versatile and efficient solution. In this article, we will delve into the history, technology, and future of flexographic printing plates, emphasizing their importance in marketing and beyond.

Understanding Flexographic Printing Plates

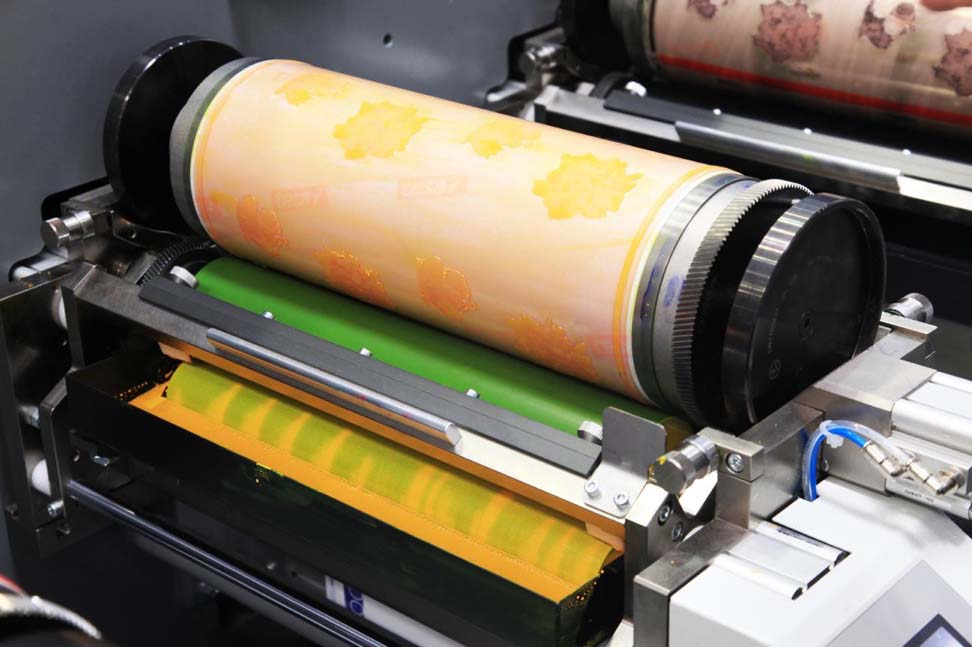

Flexographic printing plates are essential to the printing process that uses a flexible relief plate. This method is popular for printing on non-porous substrates, including plastic, metallic films, cellophane, and paper. The process allows for high-speed production and is widely used in commercial printing.

History of Flexographic Printing

The roots of flexographic printing can be traced back to the early 20th century. Initially, the technique was considered inferior due to the limitations in the quality of printing. However, advances in plate making, inks, and machinery have transformed it into a leading printing method worldwide. For more on the history and development, visit flexographic printing process.

The Impact on Marketing

For marketing professionals, understanding how flexographic printing plates impact the industry is vital. Customizable printing allows brands to experiment with their designs, producing vibrant and consistent outcomes that can be replicated across vast quantities. This consistency is crucial for maintaining brand image and message.

Components and Technology

The Role of Ink in Flexographic Printing

The ink used in flexographic printing plays a critical role in defining the quality of the printed product. Water-based and ultraviolet curing inks are commonly used, enabling quick drying times and vibrant colors. Learn more about how flexographic printing ink enhances modern printing techniques.

Technical Advantages of Flexographic Printing

Significant advantages include the ability to print on a wide variety of substrates. Flexographic printing is renowned for its efficiency and cost-effectiveness. A detailed breakdown of prints cost demonstrates its budgeting advantages in large-scale production.

Customizable Design and Branding

The flexibility of flexographic printing allows marketers to incorporate custom designs. The evolution of digital plate making technology ensures that plates can quickly adapt to new design requirements, making them ideal for brands wishing to maintain a contemporary edge.

Applications in Modern Industries

Packaging Industry

The packaging industry remains a dominant user of flexographic printing plates. Their ability to print on versatile materials makes them ideal for creating eye-catching packaging designs that stand out on the shelves.

Consumer Product Labeling

Labels for consumer products often utilize flexographic printing due to its cost-effectiveness and high-speed capabilities. This method supports the printing of detailed images, necessary for product instructions and branding alike.

The Future of Flexographic Printing

Innovation and Sustainability

The future promises continued innovation in flexographic technology. Sustainable practices are increasingly incorporated into printing processes, with an emphasis on reducing waste and using eco-friendly materials.

Integration with Digital Technologies

As the printing industry evolves, there is a notable shift towards integrating digital technologies with traditional flexographic techniques. Digital advances allow for improved precision and further customization capabilities. Detailed comparisons between flexographic and digital technologies can be explored here.

Conclusion

In summary, flexographic printing plates have significantly impacted the marketing and printing industries. With their continued evolution, they remain a pivotal element in production, promising a blend of tradition and innovation. For those in marketing, understanding the depth and applications of this technology is indispensable.

FAQs

What materials can be printed using flexographic plates?

Flexographic plates can print on a variety of materials, including plastic, paper, and metallic substrates, making them incredibly versatile for different printing needs.

Why choose flexographic printing over other methods?

This printing method is chosen for its expedience, cost-effectiveness, and ability to maintain high-quality results across large production runs.

How is sustainability addressed in modern flexographic printing?

Modern advancements focus on sustainable materials and processes, ensuring that the method is both efficient and environmentally friendly. For more information, explore external insights from here.