In the world of printing, choosing the right method can be the key to success for your marketing needs. When it comes to mass production of labels, packaging, or any other print material, both flexographic vs offset printing stand out as popular choices. Understanding the differences between these two printing techniques can greatly enhance your marketing strategy. This article delves into the intricacies of flexographic vs offset printing, providing insights valuable to marketing professionals.

Understanding the Basics of Printing Techniques

Both flexographic and offset printing have been integral to printing industries around the globe. While both techniques are used for large scale production, each has its own unique processes and benefits.

What is Flexographic Printing?

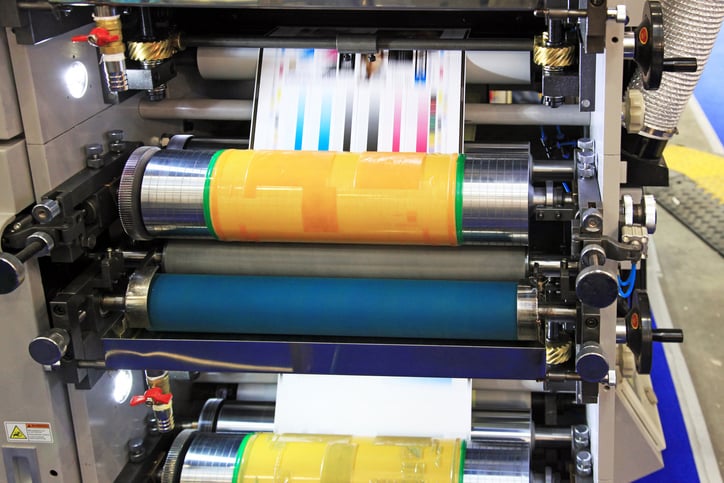

Flexographic printing employs flexible relief plates to print on a wide variety of substrates. It is known for its ability to print on non-porous materials required for various kinds of food packaging and labeling. Also called ‘flexo’, this method is ideal for continuous patterns.

For more detailed insights into flexographic printing, you can visit this guide on how flexographic printing works.

What is Offset Printing?

Offset printing, on the other hand, uses a completely different approach. Here, an inked image is transferred from a plate to a rubber blanket and then to the printing surface. This process is great for achieving high and consistent quality imagery, often used for producing brochures, books, and stationery.

Explore more about offset techniques through our brochure printing guide.

Applications: Flexographic vs Offset Printing

Different types of printing fulfill different demands. Here we compare their applications, which can influence the choice of technique for marketing professionals.

Flexographic Printing in Action

Flexo is considered the best choice for packaging involving flexible materials. It is widely used for printing on plastic, metallic films, and brown paper. Industries utilizing flexo printing include food and beverage, pharmaceutical, and household goods.

Offset Printing Preferences

For images and materials requiring high-quality reproduction, offset printing is preferred. This printing method shines in producing brochures, catalogs, business cards, and stationery. Its ability to precisely replicate images make it indispensable for high-end commercial printing.

Advantages: Flexographic vs Offset Printing

Choosing between flexographic and offset printing involves understanding the advantages each offers.

Benefits of Flexographic Printing

One of the key benefits of flexographic printing is its ability to print on a variety of surfaces with consistent quality and at high speeds. Its setup costs are relatively low, suitable for long print runs.

For detailed insights regarding the cost breakdown of different print materials, consider checking out the cost breakdown of brochure printing.

Why Choose Offset Printing?

Offset printing provides sharp and clean images on flat surfaces. It is highly efficient for large volumes of prints where color fidelity and detail matter significantly. The reproducibility it offers is second to none.

Flexographic vs Offset Printing: Industry Considerations

Each printing style’s suitability highly depends on industry-specific needs. Knowing who uses what can better inform your decisions as a marketing professional.

Flexographic Printing Industry Uses

Flexo is often utilized where continuous, large volume production runs are required. From labels to packaging products, its efficiency cannot be overstated.

Offset Printing Industry Uses

Offset printing continues to be a valuable asset in the publishing industry, where high-quality print is non-negotiable. From newspapers to coffee table books, offset printing reigns supreme.

To understand a comprehensive comparison between these printing techniques and digital printing, explore flexographic vs digital printing.

Conclusion: Flexographic vs Offset Printing

In conclusion, choosing between flexographic and offset printing should be a decision based on your marketing needs, goals, and budget. Each style brings unique advantages suited for particular materials and products. Understanding the nuances of both can empower marketing professionals to create products that resonate well with their target audience.

FAQs: Flexographic vs Offset Printing

What is the main advantage of flexographic printing?

Flexographic printing is ideal for continuous patterns at high speeds and on flexible materials, making it a versatile choice for packaging.

Can offset printing be used for packaging?

Yes, offset printing can be used for packaging, though it is more commonly associated with producing high-quality stationery and promotional materials.

Which printing method is more cost-effective?

The cost-effectiveness depends on specific needs and volumes; flexographic printing is generally more economical for long runs, while offset is better for high-quality small to medium runs.

Consider visiting this article on the flexo printing process to further explore printing techniques.