The world of printing can be vast and complex, but with the right guidance, setting up an offset press can be a straightforward task. For marketing professionals and anyone involved in the printing industry, understanding how to set up an offset press effectively is crucial for ensuring high-quality results. In this article, we will delve into the necessary steps and considerations to enhance your printing operations.

Understanding the Basics of Offset Printing

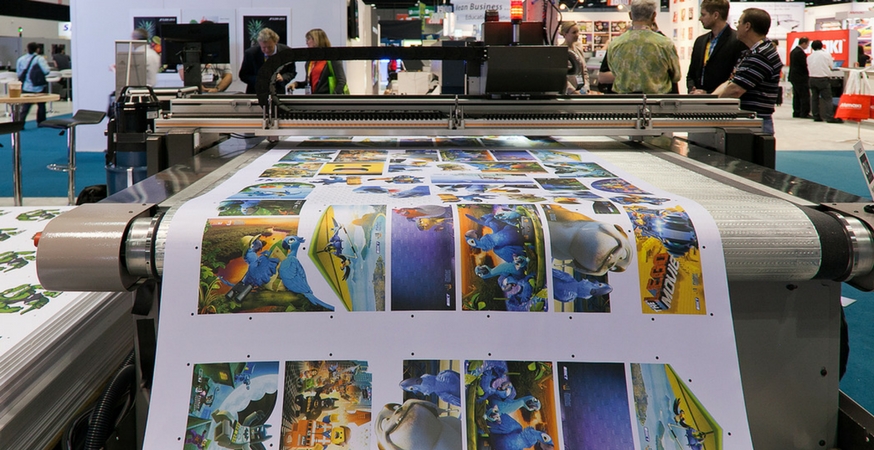

Before diving into the setup process, it’s important to comprehend what offset printing is. This method, which is widely used for producing high-volume materials like newspapers and magazines, involves transferring an inked image from a plate to a rubber blanket, and then onto the printing surface. This technique is favored for its ability to produce consistent, high-quality images and its cost-effectiveness for large runs.

Why Choose Offset Printing?

Offset printing is known for its efficiency and quality. It allows for fast production times and the ability to use a wide range of paper types and sizes. Moreover, it offers superior color fidelity and sharpness compared to digital alternatives. If you’re interested in exploring more about the differences, you can check out this comparison of digital and offset printing.

Preparing Your Workspace

To set up an offset press, you’ll first need to prepare your workspace. Ensure that the area is clean, well-lit, and free of dust and debris. The presence of contaminants can greatly affect the quality of your print jobs and the longevity of your equipment.

Safety Precautions

Safety is paramount. Make sure that all operators are familiar with the safety protocols. You can find more information on maintaining a safe environment in our related article on pressroom safety protocols.

Selecting the Right Equipment

Choosing the right offset press is crucial. Consider the volume and type of work you’ll be doing. There are various models available, each suited for different tasks and production scales.

Types of Offset Presses

There are mainly two types: sheet-fed and web-fed presses. Sheet-fed presses are ideal for small to medium-sized runs and can handle a variety of paper sizes. In contrast, web-fed presses are designed for high-volume production and are commonly used for printing newspapers and magazines.

Setting Up the Press

Now, let’s get into the nuts and bolts of setting up your offset press.

Installing the Plates

The first step in the actual setup is installing the printing plates. Ensure that the plates are properly aligned to avoid any misprints. Misalignments can lead to registration issues, which we discuss in detail in our guide on the importance of registration marks.

Adjusting the Ink Settings

Proper ink adjustment is vital. Too much ink can cause smudging, while too little can lead to faded prints. Adjust the ink density according to the specifications of your print job and conduct test runs to ensure quality.

Calibrating the Printing Press

Calibration is another critical step. This involves adjusting the press settings to ensure that the printed output matches your expectations in terms of color and quality.

Running a Test Print

Before proceeding with the full print run, always perform a test print. This step is essential to verify that all settings are correct and to make any necessary adjustments. It helps in identifying issues early, saving time and resources.

Monitoring the Print Run

Once your press is set up and running, continuous monitoring is important. Keep an eye on the print quality and make adjustments as needed. Regular checks ensure that any deviations in quality are promptly addressed.

Maintenance and Troubleshooting

Proper maintenance of your offset press is vital for longevity and efficiency. Regular cleaning and timely replacement of worn parts will prevent breakdowns and maintain print quality.

Common Issues and Solutions

Some common issues include ink smudging, plate misalignment, and paper jams. Having a troubleshooting guide handy can be beneficial. For more detailed explanations, our article on offset lithography offers insights into resolving these issues.

FAQ Section

- What is the primary benefit of using offset printing? Offset printing provides high-quality prints and is cost-effective for large runs.

- How can I ensure the longevity of my offset press? Regular maintenance and following the manufacturer’s guidelines are key to ensuring your press remains in good condition.

- What should I do if my print quality is poor? Check for proper ink levels, plate alignment, and press calibration. Conducting test prints can help identify and resolve quality issues.

In conclusion, setting up an offset press requires careful planning and attention to detail. By understanding the steps involved and maintaining your equipment, you can achieve excellent print results. For further reading and resources, consider visiting Ordant’s guide on offset printing.

This article contains affiliate links. We may earn a commission at no extra cost to you.