For print shop owners and managers, choosing the right printing technology is a decision that directly impacts profitability, efficiency, and client satisfaction. Among the various options available, latex printing has gained significant attention for its versatility and environmental benefits. But is latex printing cost effective enough to justify its adoption in a professional setting? This article examines the real-world economics, operational considerations, and long-term value of latex print systems for commercial shops.

We’ll explore how latex printers compare to other technologies, break down the main cost factors, and highlight ways to maximize return on investment. If you’re considering upgrading your shop or adding new capabilities, understanding the financial side of latex printing is essential.

Before diving into the detailed analysis, it’s helpful to understand how latex technology works and what sets it apart. For a deeper look at how these prints hold up over time, see our guide on how long latex prints last.

Understanding Latex Printing Technology

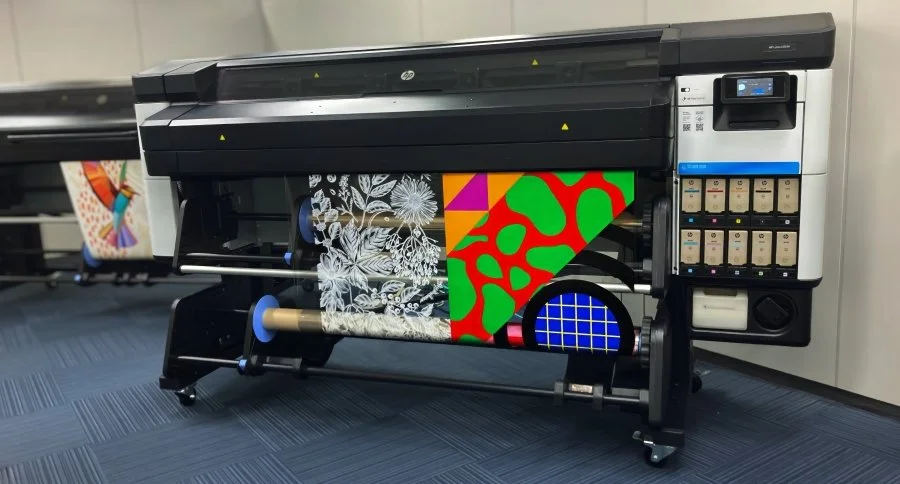

Latex printers use water-based inks that contain latex polymers, which are cured using heat to produce durable, flexible, and vibrant prints. This process is distinct from solvent or eco-solvent printing, which relies on chemical-based inks. The result is a print that is not only visually appealing but also suitable for a wide range of substrates, including banners, textiles, wall coverings, and vehicle wraps.

One of the main selling points of latex printers is their ability to deliver high-quality output with minimal environmental impact. The inks are odorless, and the prints are ready for immediate use or finishing, reducing turnaround times and improving shop productivity.

Breaking Down the Costs: Initial Investment and Ongoing Expenses

To determine whether latex printing is a cost-effective solution for professional shops, it’s important to consider both the upfront and recurring costs.

- Equipment Cost: Latex printers typically require a higher initial investment compared to entry-level solvent printers. However, the price gap has narrowed as technology has matured and more models have entered the market.

- Ink and Consumables: While latex ink cartridges can be more expensive per unit than some solvent options, they often yield more prints per cartridge due to efficient ink usage and less waste. Additionally, latex prints may not require lamination for many indoor and short-term outdoor applications, saving on finishing costs.

- Energy Consumption: Latex printers use heat to cure the ink, which can increase electricity costs. However, modern machines are designed for energy efficiency, and the faster drying process can offset the added power usage by reducing production time.

- Maintenance: These printers generally require less frequent maintenance than solvent systems, as water-based inks are less likely to clog printheads and the machines often include automated cleaning cycles.

Comparing Latex Printing to Other Technologies

When evaluating cost efficiency, it’s useful to compare latex printing with other popular methods such as solvent, eco-solvent, and UV-curable printing. Each technology has its own strengths and drawbacks, but latex stands out in several key areas:

- Versatility: Latex printers can handle a wider range of materials without the need for special coatings or primers.

- Turnaround Time: Prints are dry and ready for finishing or delivery immediately, which can speed up workflow and reduce labor costs.

- Health and Safety: Water-based inks produce fewer harmful emissions, reducing the need for expensive ventilation systems and creating a safer work environment.

- Outdoor Durability: Latex prints are known for their resilience to weather and UV exposure. For more on this, see our article on weather resistance of latex prints.

For a detailed breakdown of how latex compares to other options, check out this comprehensive guide to latex printers and their business value.

Key Factors That Influence Cost-Effectiveness

The answer to whether latex printing is cost effective depends on several variables unique to each shop:

- Volume of Production: Shops with higher print volumes benefit more from the efficiency and speed of latex printers, which can handle large jobs with minimal downtime.

- Type of Applications: If your business focuses on products that require fast turnaround, odorless prints, or a broad range of substrates, latex technology can provide a competitive edge.

- Labor and Workflow: The immediate drying and reduced finishing steps streamline operations, potentially lowering labor costs and increasing throughput.

- Print Quality and Consistency: Latex printers are known for vibrant, consistent color output. For tips on maximizing color impact, see our advice on tips for vibrant latex prints.

Maximizing Value: Practical Tips for Shop Owners

To get the most from your investment in latex printing, consider these practical steps:

- Optimize Print Settings: Use the recommended best resolution for latex printing to balance quality and ink consumption.

- Regular Maintenance: Follow manufacturer guidelines for cleaning and calibration to extend equipment life and maintain output quality.

- Material Selection: Choose substrates that are compatible with latex inks to avoid unnecessary waste and reprints.

- Monitor Energy Usage: Schedule large print jobs during off-peak hours if possible to take advantage of lower electricity rates.

- Stay Informed: Keep up with the latest advancements in latex ink and printer technology to ensure your shop remains competitive.

Environmental and Regulatory Considerations

Beyond direct financial costs, latex printing offers advantages in terms of compliance and sustainability. The water-based inks meet many indoor air quality standards, and the absence of hazardous air pollutants can simplify permitting and reduce regulatory burdens. This can translate into indirect cost savings, especially for shops operating in regions with strict environmental controls.

Additionally, the ability to print on recyclable and eco-friendly materials can open new business opportunities and appeal to environmentally conscious clients.

Frequently Asked Questions

How does latex printing compare to solvent printing in terms of long-term costs?

While latex printers may have a higher initial purchase price, their lower maintenance needs, reduced finishing steps, and faster turnaround can lead to lower total operating costs over time. Many shops find that the investment pays off through increased productivity and broader application possibilities.

Are latex prints durable enough for outdoor use?

Yes, latex prints are highly durable and resistant to weather, UV exposure, and abrasion. For more details on longevity, see our article on how long latex prints last.

What are the main maintenance requirements for latex printers?

Maintenance is generally straightforward, involving periodic printhead cleaning and calibration. Automated cleaning cycles help minimize downtime, and water-based inks reduce the risk of clogging compared to solvent systems.

Can latex printers handle specialty applications?

Absolutely. Latex technology is suitable for a wide range of applications, including textiles, wall coverings, vehicle graphics, and more. The versatility of substrates and immediate drying make it a strong choice for shops looking to expand their offerings.

Conclusion: Is Latex Printing a Smart Investment?

For many professional print shops, latex printing offers a compelling balance of quality, versatility, and operational efficiency. While the initial investment may be higher than some alternatives, the long-term savings in labor, maintenance, and finishing—along with the ability to serve a broader client base—often make it a financially sound choice. By carefully considering your shop’s production needs and following best practices for operation and maintenance, you can maximize the cost-effectiveness of this technology.