In the vibrant world of flexographic printing, professionals are often confronted with various challenges. One such prevalent issue is pinholing in flexo. Understanding and addressing this concern is vital for those striving to achieve optimal printing outcomes.

In this comprehensive article, we’ll delve into the intricacies of pinholing in flexo, exploring its causes, effects, and practical solutions to help marketing professionals and other stakeholders enhance their printing results.

Understanding Pinholing in Flexo

Pinholing refers to the presence of small, unintended holes on the printed surface, which can adversely affect print quality. In flexo printing, these tiny imperfections are a common issue, especially when dealing with porous substrates or improper ink formulations.

Causes of Pinholing in Flexo

Several factors can lead to the occurrence of pinholing in flexo printing:

- Ink viscosity: Ink that is too thick or thin can result in uneven coverage, leading to pinholes.

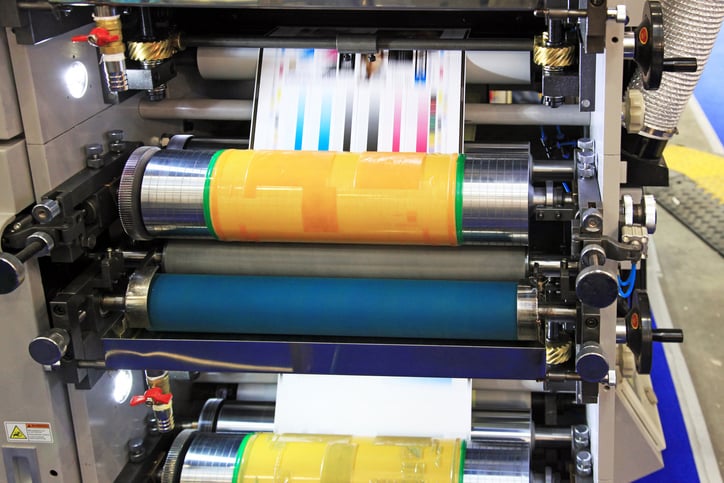

- Anilox roll condition: A worn-out or improperly cleaned anilox roll can lead to inadequate ink transfer.

- Printing pressure: Insufficient pressure between the plate and the substrate can cause irregular ink distribution.

The Impact of Pinholing on Print Quality

Pinholing can significantly diminish the visual appeal of printed materials. This imperfection can harm brand perception and decrease the overall effectiveness of marketing materials, making it crucial for professionals to address the issue promptly.

Identifying Pinholing

Inspecting printed materials under bright light can help identify pinholing. Look for small, unprinted spots that can suggest ink application issues.

Solutions to Minimize Pinholing in Flexo

Adopting specific strategies can greatly reduce the occurrence of pinholing in flexo:

- Optimizing ink formulation: Adjusting ink viscosity can lead to more even application across the substrate.

- Regular maintenance of printing equipment: Ensure anilox rolls are clean and in good condition for consistent ink transfer.

- Calibration of printing pressure: Adjusting pressure settings can help achieve better contact between the plate and substrate.

Role of Ink Suppliers

Collaborating with ink suppliers can be beneficial as they can provide tailored formulations to address specific pinholing issues.

Case Studies on Pinholing in Flexo Printing

Several companies have successfully managed pinholing by implementing strategic solutions. For instance, a notable packaging firm improved its print quality by collaborating with ink suppliers for optimized ink formulations.

Continuous Improvement in Flexographic Printing

Addressing pinholing requires ongoing attention to detail and regular assessments of printing processes to ensure high-quality results. For further information on enhancing printing techniques, explore flexo printing process.

Concluding Thoughts

The issue of pinholing in flexo demands a comprehensive approach, combining regular equipment maintenance, ink formulation adjustments, and collaboration with industry experts. With these strategies, marketing professionals can achieve superior print quality and enhance their marketing materials’ effectiveness.

For Further Exploration

Interested in diving deeper into the mechanics of flexographic printing? Check out our detailed guide on plate making for insights into critical stages of the printing process.

FAQs About Pinholing in Flexo

What are common causes of pinholing?

Common causes include improper ink viscosity, damaged anilox rolls, and incorrect printing pressure.

How can I reduce pinholing in my prints?

Consider adjusting ink formulations, maintaining equipment, and calibrating printers to minimize pinholing. Consulting with experts can also be beneficial.

Can pinholing affect brand perception?

Yes, pinholing can detract from print quality, affecting the visual appeal of marketing materials and, consequently, brand perception.