The world of flexo printing is vast and varied, offering marketing professionals an array of opportunities to produce high-quality prints with efficiency. One crucial component of this process is the concept of prepress in flexo printing. This initial segment of the printing workflow significantly influences the final output, making it a critical area of focus for anyone interested in high-quality results.

Prepress in flexo printing involves the preparation and setup required before the actual printing begins. This phase ensures that all design elements are correctly formatted and ready for transfer onto the printing substrate using a flexographic press. Understanding this step is essential for marketing professionals looking to optimize their print projects and achieve outstanding results.

What is Flexo Printing?

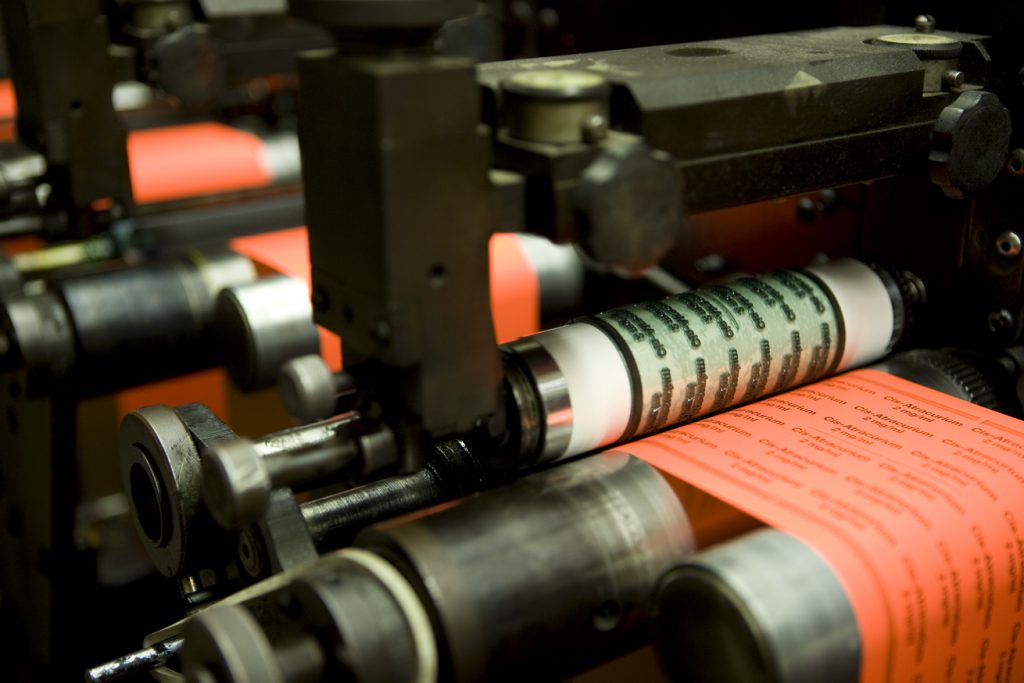

Before delving deeper into the prepress process, it’s essential to understand what flexo printing entails. Flexographic printing, or flexo printing, is a technique that uses flexible relief plates to transfer ink onto various substrates. It is commonly used in packaging and label production due to its versatility and efficiency. You can learn more about integral steps like plate making at Plate Making.

The Importance of Prepress

The prepress stage involves several steps, each aimed at ensuring the print job proceeds smoothly and the end results meet quality expectations. This stage is crucial as it addresses elements like image resolution, color accuracy, and layout configurations. Any mishaps during prepress can lead to costly errors during main production.

Components of Prepress in Flexo Printing

Artwork Design and Preparation

The first step involves designing and preparing artwork. Designers must ensure that their graphics are formatted correctly for flexographic processing. Elements like bleed, crop marks, and resolution need careful consideration to avoid issues during printing.

Color Management

Effective color management is pivotal to producing vivid and accurate prints. Prepress technicians need to work with exact color profiles to ensure that the inks used in flexo printing reflect the intended design. Understanding color theory is imperative in this context.

Screening and Raster Image Processing (RIP)

The RIP process translates digital images and text into a format suitable for printing. Proper screening ensures that images are rendered with the correct dot size and frequency, which is crucial for image clarity and detail.

Plate Making

Plate making is a pivotal part of prepress in flexo printing. This process creates the printing plates that will transfer ink to the substrate. Consistency in plate making ensures precise image reproduction. Discover the nuances of this process through resources on plate creation.

Calibration and Quality Control

Calibration

To achieve reliable results, printing equipment must be calibrated according to the specifications of the print job. This step includes adjusting the flexographic press to align with the artwork’s layout and ensuring the reproductions meet desired standards.

Quality Control Checks

Quality control is integral to prepress procedures, focusing on detecting any potential issues before full-scale production. By identifying problems early, companies can prevent material wastage and save resources.

Technological Innovations in Flexo Prepress

Advanced Software Solutions

Modern advancements have seen the introduction of software tools that simplify the prepress process. These solutions streamline workflow and enhance precision, thus reducing human error.

Automation

With the advent of automation, many repetitive prepress tasks are now handled by machines, allowing for increased efficiency and reduced chances of error, which translates to better overall print quality.

Navigating Common Prepress Challenges

Overcoming Design Errors

Common challenges in prepress include dealing with design errors stemming from incorrect formatting or layout issues. Regular checks and using the correct design software can help mitigate these problems.

Addressing Plate Issues

Improper plate making can lead to defects in the printing process. Maintaining consistency during the photopolymer plate creation can prevent such problems, offering a seamless printing experience.

Conclusion

Understanding and implementing effective prepress in flexo printing is crucial for marketing professionals looking to achieve superior print quality. By paying attention to details from the initial artwork design to plate making, the results not only meet but often exceed expectations. Utilizing resources like flexographic on cartons ensures a comprehensive grasp of the flexo printing process.

FAQs

What is the role of prepress in flexo printing?

The prepress in flexo printing involves preparing design and print materials to ensure they are ready for the printing process. It includes artwork design, color management, and plate making.

Why is color management important in prepress?

Color management ensures that the colors on the final print match the intended design. This accuracy is vital to meet client expectations and maintain brand consistency.

How has technology improved flexo prepress processes?

Modern technology has introduced efficient software and automation that reduce errors, streamline workflow, and improve the precision of prepress tasks in flexo printing. Explore more about this on [Flexo Printing Insights](https://brandims.com/what-is-flexographic-printing-a-guide/).