The world of printing is vast and varied, yet one method stands out for its precision and widespread use: offset printing. At the heart of this technique is the crucial stage known as prepress in offset printing. This phase ensures that every print job is executed flawlessly, making it indispensable for achieving high-quality results. Understanding prepress processes is essential for marketing professionals and anyone involved in the printing industry.

What is Prepress?

Prepress refers to all the preparatory steps taken before a print job is actually produced. It includes a range of activities from designing, proofreading, and layout settings to ensuring that all elements are ready for the printing press. This stage is crucial to prevent errors and ensure efficiency in the printing process.

The Importance of Prepress in Offset Printing

In offset printing, prepress is vital because it impacts the final output quality. By meticulously preparing all materials beforehand, businesses can avoid costly mistakes and delays. The prepress stage involves multiple checks and adjustments to ensure that the colors, images, and layouts are perfect for the specific print job.

Key Steps in the Prepress Process

Lets delve deeper into the essential steps involved in the prepress in offset printing:

Design Creation

The first step is creating a design that meets the client’s specifications. This involves using graphic design software to craft layouts, select color schemes, and ensure that the visual elements align with the intended message.

Proofreading and Editing

Before moving forward, the content needs to be thoroughly proofread. This step ensures that there are no typographical errors or inconsistencies that could affect the print quality.

Color Management

Color accuracy is crucial in offset printing. The prepress stage involves adjusting color profiles and calibrating monitors to match the print output. Tools such as colorimeters are often used to achieve this precision.

File Preparation

Preparing files for printing is another vital component. This involves converting files into formats suitable for printing, such as PDF, and ensuring they are compatible with the printing equipment.

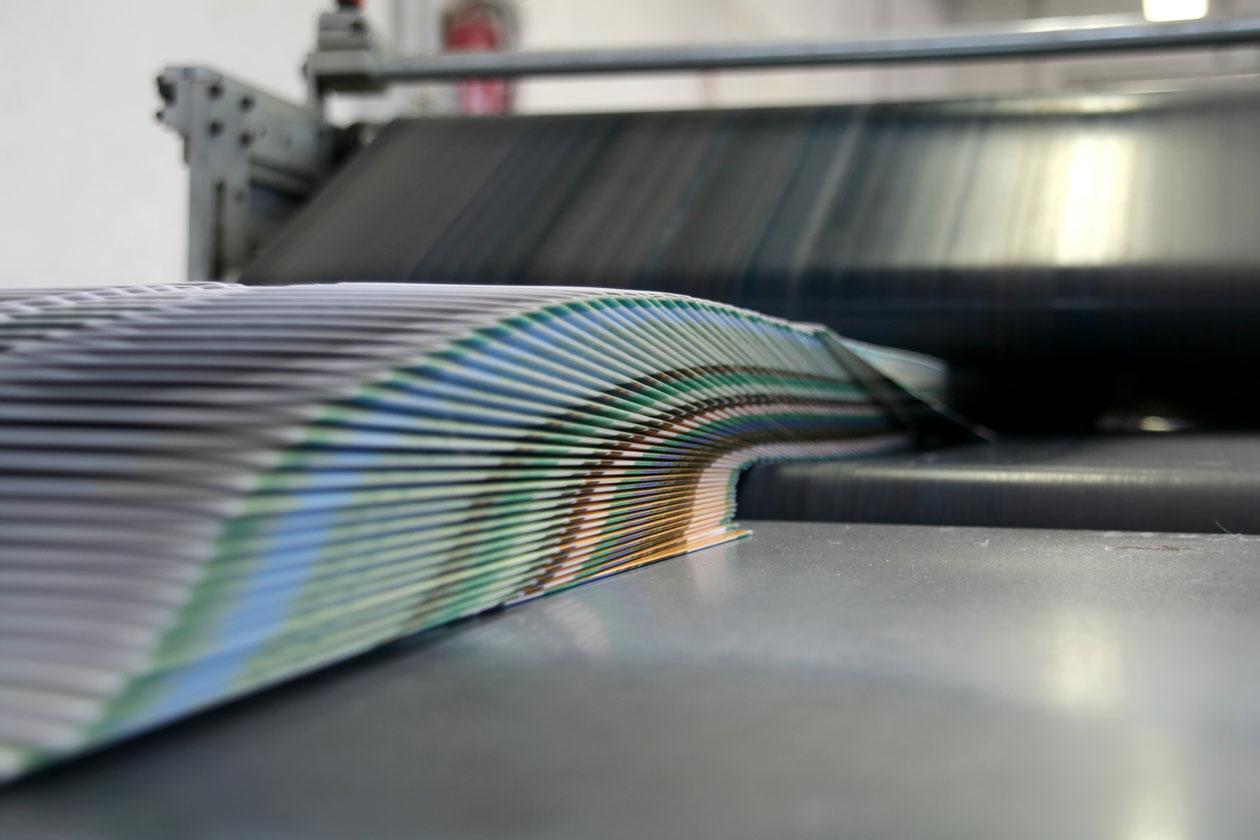

Plate Making

In offset printing, plates are used to transfer ink onto paper. The prepress stage includes creating these plates, which involves etching the design onto metal sheets.

Technology in Prepress

Advancements in technology have revolutionized the prepress stage. Software tools and automated systems have streamlined processes, making them more efficient and less prone to error. This has allowed printing companies to deliver high-quality results at a faster pace.

Challenges in Prepress

Despite technological advancements, the prepress stage still presents challenges. These include maintaining color consistency across different media, managing complex designs, and ensuring that digital files are error-free.

Benefits of a Well-Executed Prepress Process

A well-executed prepress process leads to numerous benefits, such as reduced waste, lower costs, and improved print quality. It ensures that the final product meets the client’s expectations and adheres to industry standards.

Why Marketing Professionals Should Care

For marketing professionals, understanding the intricacies of prepress in offset printing is crucial. It allows them to make informed decisions about their print materials, ensuring that their campaigns are visually appealing and effective.

Conclusion: The Future of Prepress in Offset Printing

The future of prepress in offset printing is promising, with ongoing innovations enhancing its efficiency and accuracy. As the printing industry continues to evolve, staying informed about these developments will be key for professionals looking to leverage printing for their marketing strategies.

Further Reading

For more insights into offset printing, visit the Thomas Group Printing or explore the Wikipedia page on offset printing. Additionally, learn about the differences between offset and laser printing, and explore how offset printing is used in magazines.

FAQs

What is the role of prepress in printing?

Prepress plays a critical role in preparing all materials and ensuring they are ready for printing. It involves design, proofreading, color management, and file preparation.

Why is color management important in prepress?

Color management ensures that the colors on the printed material match the design specifications. It is crucial for maintaining brand consistency and achieving the desired aesthetic.

How has technology improved prepress processes?

Technology has introduced automation and advanced software tools that streamline prepress processes, reduce errors, and enhance the overall efficiency of printing jobs.

This article contains affiliate links. We may earn a commission at no extra cost to you.