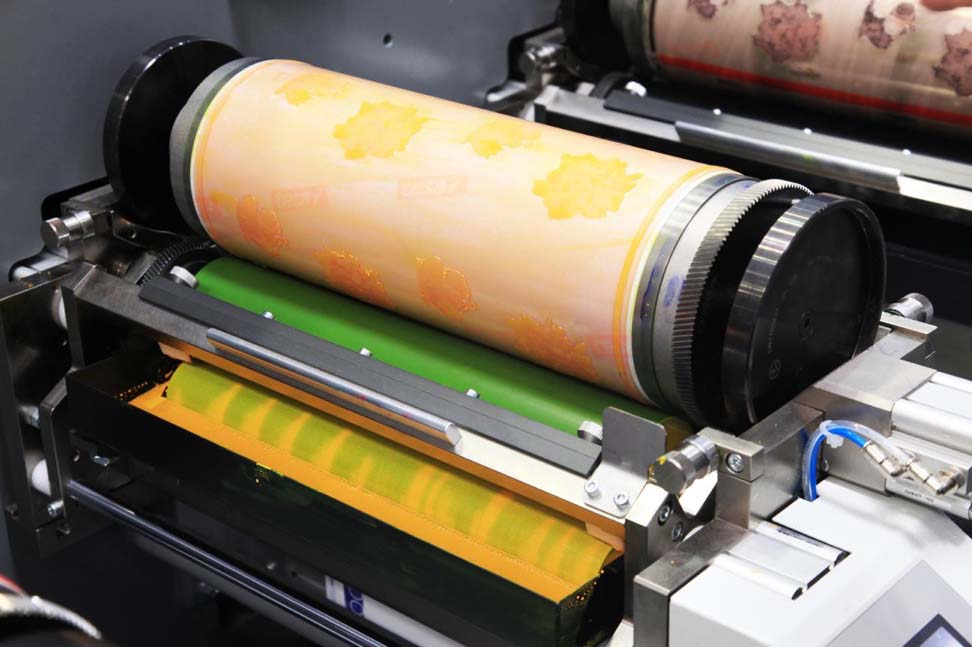

In the world of flexographic printing, understanding the sleeve life is crucial for maintaining efficiency and quality. The sleeve, an essential component in the printing process, plays a pivotal role in ensuring precision and consistency. But what exactly is the sleeve life in flexographic printing, and why does it matter?

The sleeve life refers to the duration or lifespan of a printing sleeve before it needs replacement. This is a vital aspect to consider for any business involved in flexographic printing as it directly impacts the cost, efficiency, and quality of the printing operations.

What Affects Sleeve Life?

Several factors influence the sleeve life in flexographic printing. These include the type of materials used, the frequency of use, and the maintenance practices employed. Understanding these factors can help in extending the sleeve life and optimizing the printing process.

Materials are a critical component. High-quality materials generally result in a longer-lasting sleeve. Additionally, how often the sleeve is used and the conditions it is exposed to during printing operations can significantly affect its lifespan.

Importance of Quality Materials

Using quality materials can greatly enhance the sleeve life in flexographic printing. Durable materials not only withstand the rigors of the printing process but also reduce the frequency of replacements, contributing to cost savings in the long run.

Investing in high-grade sleeves can also improve the quality of the print output. This is crucial for businesses looking to maintain a high standard of printing quality, especially in industries where precision is paramount.

Proper Maintenance Practices

Maintenance is another key factor in determining the sleeve life. Regular inspection and proper cleaning can prevent damage and wear, extending the sleeve’s usefulness. Implementing a routine check-up schedule and using appropriate cleaning agents can prevent the deterioration of the sleeve.

Avoiding Common Mistakes

Many businesses make the mistake of neglecting sleeve maintenance, which can lead to premature wear and tear. Ensuring that sleeves are stored properly, away from excessive heat and moisture, is crucial in maintaining their longevity.

Advancements in Flexographic Printing

The printing industry is continuously evolving, with new technologies improving the efficiency and lifespan of printing sleeves. Innovations in sleeve manufacturing and materials are offering better durability and performance. Staying updated with these advancements can be beneficial for businesses aiming to optimize their printing operations.

Technological Innovations

Advancements in technology have led to the development of sleeves that are more resistant to wear and tear, thereby extending their life. These innovations include enhanced materials and manufacturing processes that offer greater durability and performance.

Cost Implications

The cost of replacing sleeves is a significant consideration for any printing business. Understanding the sleeve life can help in planning and budgeting for replacements, ensuring that unexpected costs do not disrupt the business operations.

Businesses can achieve cost savings by investing in durable sleeves and implementing effective maintenance practices. This not only extends the sleeve life but also reduces the need for frequent replacements.

Impact on Print Quality

The condition of the sleeve directly affects the quality of the print output. Worn-out sleeves can lead to printing errors and inconsistencies, impacting the final product’s appearance. Ensuring that sleeves are in good condition is essential for maintaining high-quality print standards.

Regular inspections and timely replacements can prevent issues related to print quality, ensuring that the final product meets the desired standards of excellence.

Environmental Considerations

In today’s environmentally conscious world, the impact of sleeve replacements on the environment is an important consideration. Using durable sleeves and extending their life can minimize waste and contribute to sustainable business practices.

Implementing eco-friendly practices in sleeve maintenance and disposal can also help reduce the environmental impact of printing operations.

Conclusion

Understanding and optimizing the sleeve life in flexographic printing is crucial for any business involved in this industry. By focusing on quality materials, proper maintenance, and staying updated with technological advancements, businesses can enhance their printing operations and achieve cost savings.

For more information on flexographic printing, visit this comprehensive guide.

FAQs

What is the average sleeve life in flexographic printing?

The average sleeve life can vary depending on the materials used and the frequency of use. However, with proper maintenance, sleeves can last for several years.

How can I extend the sleeve life?

Regular maintenance, proper storage, and using high-quality materials can all contribute to extending the sleeve life.

What are the consequences of not maintaining sleeves properly?

Neglecting sleeve maintenance can lead to premature wear and tear, affecting print quality and increasing replacement costs.