The world of printing holds various techniques that help in achieving the desired quality and precision, and trapping in flexographic printing is one of the critical elements in this process. Whether you are new to the field or a seasoned professional aiming to enhance your knowledge, this article provides a comprehensive overview of trapping in flexographic printing.

As a crucial technique in the printing journey, trapping addresses potential problems that might arise due to misalignments and color overlaps. Understanding this practice is essential for marketing professionals who continually strive to maximize the effectiveness of printed materials.

Understanding Flexographic Printing

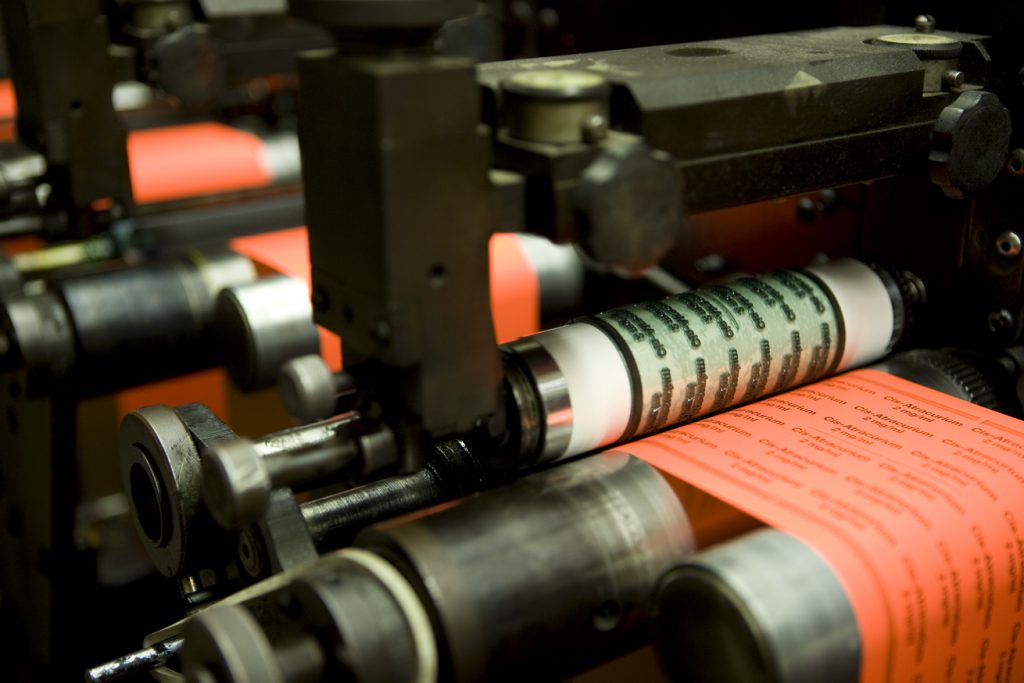

The flexographic printing process is a popular technique renowned for its adaptability and efficiency. From retail packaging and labels to newspapers and wall coverings, it shapes the printing industry. Flexography, or flexo, uses a flexible relief plate to print on various surfaces, making it extremely versatile.

The importance of flexographic printing in retail and other sectors has grown significantly, offering distinctive advantages over other printing methods.

Overview of Trapping

Trapping is a method used in printing to manage graphics and text that are meant to overlap or touch. This process prevents gaps between colors when the presses are slightly misaligned. Imagine a situation where printed elements move slightly off their intended position trapping serves as a safety net to catch these errors.

Why is Trapping Important?

In flexographic printing, where various materials and conditions play a role, ensuring that colors overlap correctly is vital. Without trapping, the final print might showcase visible gaps or misalignments. It’s about ensuring the smooth transition and blend of colors.

Core Principles of Trapping

- Width The distance defined where overlaps are to be created. It ensures that slight shifts don’t lead to misalignments.

- Direction Determines how the overlap happens, either over or under adjoining elements.

- Tint Reduction Involves modifying color densities to achieve a balanced appearance.

Steps in Implementing Trapping

1. Identifying Critical Elements

Every print comprises various elements, some more critical than others. Identifying high-priority areas where trapping needs to be applied ensures consistency.

2. Setting Ideal Trapping Values

The width and direction of trapping depend on factors like the material and print environment. These values should be adjusted according to specific project requirements, ensuring effective execution.

3. Evaluating the Final Output

Reviewing the print test results is essential. This helps in understanding whether adjustments in trapping values are needed to achieve the best output. A close analysis can indicate where further fine-tuning is required.

Common Challenges and Solutions

1. Misalignment Issues

Occasionally, press issues may result in alignment errors. Leveraging trapping ensures that such deviations don’t affect the quality of the final print.

2. Color Variations

Color consistency is fundamental in printing. Through flexo printing, trapping guarantees that variations don’t lead to drastic changes in the appearance of a printed piece.

3. Dynamic Printing Environments

The conditions under which printing happens are anything but constant. In dynamic environments, from temperature changes to varying substrates, trapping offers a protective mechanism to counteract these fluctuations.

Technological Advances in Trapping

The printing world continuously evolves, with technological advancements enhancing the trapping process. The integration of software solutions allows for more precision in trap settings, optimizing project outcomes.

Practical Examples of Trapping

You might see trapping in action on supermarket labels or magazines. The complexity and variation in design ensure trapping is invaluable in producing seamless prints.

Final Thoughts

Understanding trapping in flexographic printing is not only essential for ensuring high-quality outcomes but also acts as an educational journey for those in the marketing field.

FAQ

- What is flexographic printing primarily used for?

Flexographic printing is widely used for various applications, including packaging, labels, newspapers, and wallpaper production, due to its versatile nature.

- How does trapping improve print quality?

Trapping prevents gaps and misalignments between colors, ensuring a seamless and professional appearance in the final print.

- Are there alternatives to trapping in printing?

While other techniques exist, like color management, trapping remains a primary method for addressing alignment and overlap issues in flexographic and other types of printing.